The company

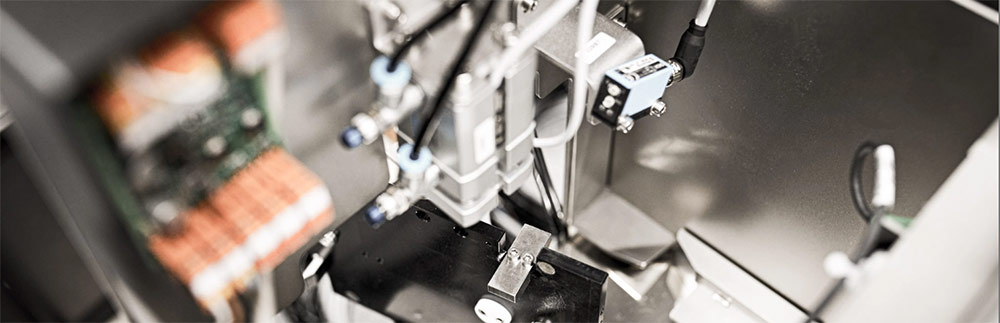

Cerescon is a rapidly developing, high-tech scale-up in Agrofood robotics. They develop and market a selective harvesting solution for white asparagus called “Sparter”. Their objective is to automate picking of white asparagus and ensure that European consumers can continue enjoying a delicious and affordable dish of locally produced fresh asparagus.