The company

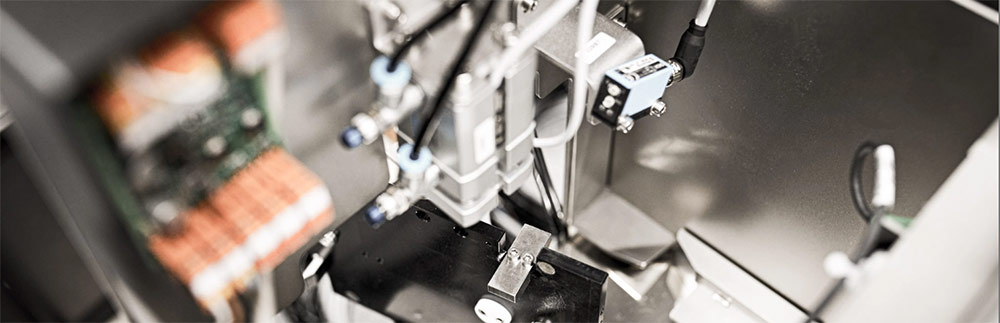

AM-Flow is a start-up that focuses on the 3D printing market. The company creates intelligent solutions designed to simplify large-scale 3D printing processes. So far, several systems have been developed, including the AM Vision 2.0.

AM-Flow specializes in artificial intelligence and machine learning. MTA has been chosen as partner for both engineering and production of the AM Vision 2.0. We achieved a short time-to-market and a system that is extremely suitable for series production.

AM-Flow is a start-up that focuses on the 3D printing market. The company creates intelligent solutions designed to simplify large-scale 3D printing processes. So far, several systems have been developed, including the AM Vision 2.0.

The challenge was to design the AM Vision 2.0 system in a short time and to produce it within the desired quality standards.

AM-Flow has made a functional model (FUMO) of the AM Vision 2.0 system. The software was central to this prototype. The FUMO proved the functionality of the system; the search algorithm worked perfectly. However, the hardware was in need of further improvement. In addition, the system had to be designed in such a way that serial production runs quickly and efficiently.

Potential customers were interested in the prototype and recognized the added value it could bring to their factory. The customers were queuing up and wanted to receive the product as soon as possible. A fast time-to-market was desired.

Several phases are important to achieve the best end result:

Manufacturability

The transfer of knowledge during the development phase enables careful documentation of requirements and wishes in the field of mechanics, electronics and software. To complete this process, mutual trust is paramount. By being open and sharing knowledge, the quality of the system can be guaranteed. The feedback from MTA’s industrialization specialist resulted in the creation of a system well suited for series production. In this phase, the total costs and the desired time-to-market were closely monitored.

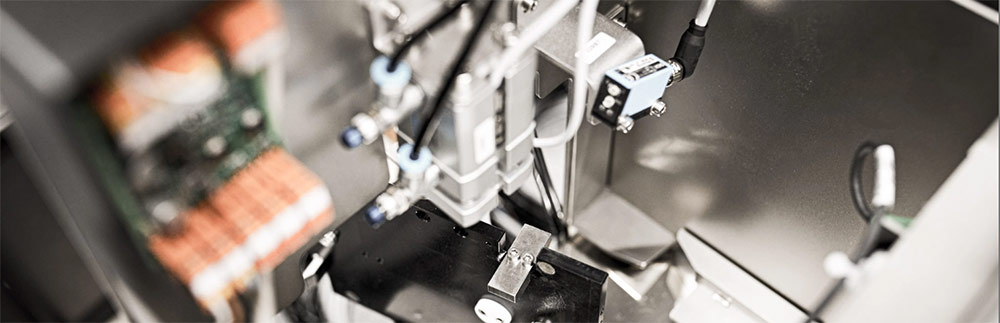

Universal System

The AM Vision 2.0 is integrated into the end user’s existing architecture. It was therefore essential to develop a universal system that can function in combination with various existing conveyor systems. This has been taken into account in the basic setup of the AM Vision 2.0, allowing the standard system to be produced in series with preset dimensions. For example, by adjusting the number of cameras in a machine, a modified version of the standard system can be created for specific customers. Also, the software used in AM Vision 2.0 can be easily connected to the assembly line software system, so that sorted items are guided in the right direction.

Worldwide ease of use

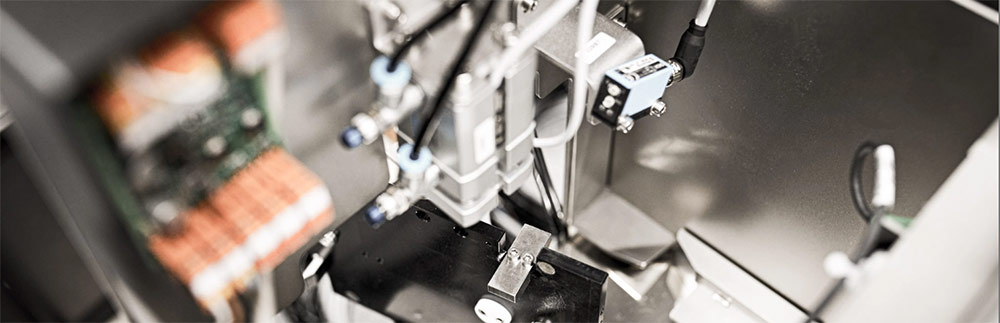

The European and American market have different quality certifications. Ensuring that the machine meets both European CE certification standards and United States UL certification standards, the system is ready to be launched in any country.

In order to design a system that functions optimally, AM-Flow has chosen to outsource the engineering and production of the complete system. By integrating the engineering and production process and outsourcing it to one party, a significantly shorter time-to-market was achieved.

Collaboration

The collaboration between AM-Flow and MTA combines the core competencies of both companies. This ensures the best result. Where AM-Flow’s main competencies lie in software Research and Development, MTA is highly skilled in advanced mechatronics and the industrialization process.

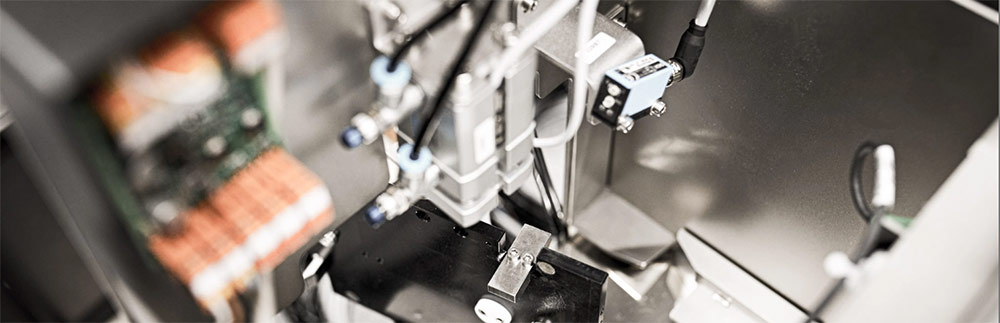

"AM-Flow specializes in artificial intelligence and machine learning. We have developed a unique search algorithm for sorting 3D objects, it is a direct answer to the market demand. But the competence to design a system that is perfectly suitable for series production is not present at AM-Flow. To enable the desired fast time-to-market, we decided to look for a partner who can help us."

As an experienced system supplier, MTA is able to integrate engineering and production through industrialization, creating an effective process with short lead times. This is of course also closely related to a fast time-to-money. That is extra important for a start-up. The system is ready for series production and upscaling, including optimum manufacturability and reproducibility.

MTA determines which parts are crucial to achieve an optimal production process. In addition, we use an international supply chain that contributes to a competitive integral cost price.

"Working closely with MTA, we were able to create a system that responds directly to market demand. In addition, the system can be sold anywhere in the world. MTA's expertise in mechatronics and industrialization has ensured that engineering and manufacturing have been integrated into one efficient process."